|

상품정보

견적자료 요청하기

구매사이트로 이동하기

브로셔 다운로드

|

| 상품설명 | ||||

연료, 기유, 조제유 및 기타 석유 화학 유체 화학 물질 및 희석 된 중합체에 적용 가능

› 동점도 및 희석 용액 점도 표준과 관련된 모든 ASTM, EN, ISO 및 DIN 표준을 충족합니다.

› 매우 정확한 온도 제어

› 유체 유형에 관계없이 매우 정확한 유량 측정

› 진공 또는 압력 방법으로 점도계 충전

› 적은 시료량 / 적은 용매 소비

› 높은 수용력 ; 시간당 튜브 당 욕조 당 최대 10 회 측정

› 교차 오염없이 작동 할 수있는 혁신적인 점도계 튜브 세척

› 간편한 점도계 튜브 교환

› 석유 화학 유체 및 희석 용액 점도 샘플에 적합

› 광범위한 유체 및 용매에 화학적 내성

› 다양한 요구 사항을 충족하는 여러 버전 사용 가능

› 컴팩트 한 디자인

이 제품은 다음 테스트 방법을 준수합니다.

› ASTM D445

› ASTM D446

› ASTM D2270

› DIN 3104

› DIN 3105

› 플라스틱

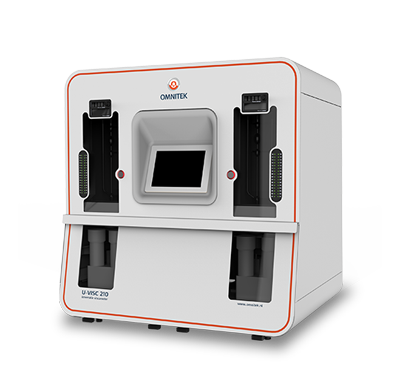

Omnitek U-VIsc는 네 가지 모델로 제공됩니다

Version | Independent | Viscometer | Autosampler | Max. capacity |  |

U-VIsc 110 | 1 | 1 | 16 positions | 10 meas. | |

U-VIsc 120 | 1 | 2 | 16 positions / tube | 20 meas. | |

U-VIsc 210 | 2 | 1 | 16 positions / tube | 20 meas. | |

U-VIsc 220 | 2 | 2 | 16 positions / tube | 40 meas. |

*) 시간당 측정; 선택한 점도, 튜브, 온도 및 용매에 따라 다름

사용 가능한 옵션 :

이중 솔벤트 세척

고온 수조 (150 °C)

샘플 예열기 (튜브 당 1 개; 최대 150 °C)

압축기

냉각 스파이럴 및 외부 냉각기

받침대

PC + 프린터

표준 소프트웨어

U-VIsc는 사용하기 쉬운 고급 다국어 소프트웨어를 사용합니다. 하나의 PC로 최대 4 개의 서로 다른 시스템을 제어 할 수 있습니다 (각 계측기마다 1 개의 COM 포트 필요). RS-232 또는 무선을 통해 LIMS와 데이터를 교환 할 수 있습니다. 계측기는 PC 인터페이스를 통해 전체적으로 작동 할 수 있습니다. 샘플 ID를로드하고 샘플 큐를 시작, 중지 또는 일시적으로 중단 할 수 있습니다. 결과는 내부 데이터베이스에 저장되며 선택적으로 외부 드라이브 또는 네트워크 폴더에도 저장됩니다.

실행 중에 측정 된 유량 시간, 평균, 확산 및 교정 / 점도 결과와 같은 여러 종류의 정보가 표시됩니다. 또한 충전, 청소 등과 같은 실제 상태가 관련된 모든 장치에 대해 표시됩니다. 측정 된 유량 시간은 상단 또는 하단 측정 전구가 테스트에 사용되는지에 따라 왼쪽 또는 오른쪽 열에 표시됩니다. 샘플 큐는 영구적으로 존재하며 샘플 실행을 방해하지 않고 언제든지 편집 할 수 있습니다.

U-VIsc 소프트웨어의 독특한 특징은 튜브 청소 및 건조를위한 다양한 방법을 포함하여 다양한 작동 방법을 정의하고 저장하는 기능입니다. 점도 측정 또는 교정을위한 방법을 설정할 수 있으며 여러 구성 가능한 단계가 포함됩니다.

작동 모드 점도 또는 교정

Termination Static = 고정 된 연속 측정 횟수

Dynamic = 측정 횟수는 사전 설정 조건에 따라 다름

예열 시간 점도계 튜브에서 샘플을 열적으로 안정화시키기위한 고정 시간

예열 시간 샘플 예열 시간 (참고 : 예열기 옵션)

진공 감소 점도가 낮은 충전 점도계는 저 휘발성 성분의 조기 증발을 방지하거나

가스 기포 형성을 감소시킬 수 있습니다

세척 방법 미리 정의 된 다양한 점도계 세척 방법을 선택할 수 있습니다.

Omnitek U-VIsc를 사용하면 점도계 세척을위한 몇 가지 방법을 정의 할 수 있습니다.

이것은 모든 종류의 유체 최적화 된 세척 매개 변수를 설정할 수있는 것과 같이 작동에 큰 이점을 제공합니다.

이름 정의 된 이름이 운영 방법에 표시됩니다

주입 용매 1 1 차 용매 주입 횟수 (예 : 톨루엔

주입 용매 2 2 차 용매 주입 횟수 (예 : 아세톤

사출 량 사출 당 용매 량

건조 시간 사전 설정 시간

철저한 청소 설정하면 집중적 인 솔벤트 스프레이가 가능합니다

다국어

새로운 다국어 소프트웨어를 사용하면 모든 언어로 모든 분석 절차를 제어 할 수 있습니다.

점도 지수 (VI)

VI는 자동 또는 수동으로 계산됩니다. 소프트웨어는 동일한 샘플 ID에 대해 VI를 자동으로 제공합니다.

두 개의 다른 샘플 ID를 수동으로 선택하여 VI를 계산할 수도 있습니다.